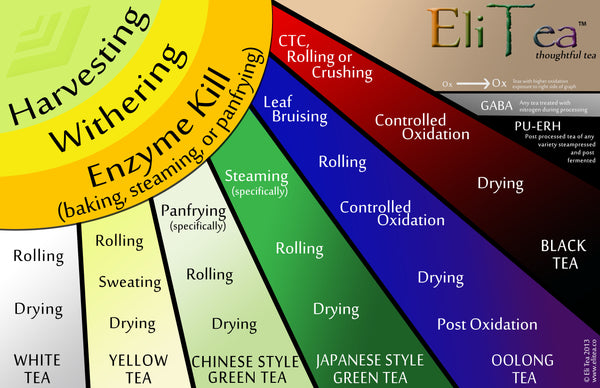

The spectrum of teas available throughout the world is vast due to climate, cultivar, and (most importantly) the processing technique. All teas are a product of the Camellia sinensis plant but are distinguished and categorized by their level of oxidation and production. Tea leaf processing can be summarized in four steps: withering, rolling, oxidation, and drying. The actual production of tea, however, is a complex process with multiple steps to each phase. Also, note that production steps are also sometimes interchanged and repeated in treatments. Tea gardens closely guard the precise methods of their processing technique, like a chef’s secret recipe. Interestingly, these nuances of production are almost entirely dependent on human skill and often stay in families for generations.

Due to all these variations and secrets, you may come across conflicting descriptions of tea processing; however, each of these methods, per se, is correct. Okakura Kakuzo, a early 20th century Japanese author of tea culture, once wrote “Like art, tea has its periods and schools.” Tea, as distinct varieties and as a whole, has had marked surges and declines in popularity and, as a result, its processing has changed over thousands of years.

I hope you will gain a general understanding of the methods and possibilities of tea processing from this post. The following is a brief walk through each of the different stages.

Processing Steps

Harvesting

Tea harvesting is a delicate process that is difficult to do quickly for fear of damaging the tea leaves. The majority of tea is still harvested by hand but mechanical picking can also be done depending on the tea variety. Manual harvesting allows for discrimination in selection where priority is placed on the younger leaf shoots, as they are the highest in caffeine and antioxidants. This is also the derivation of the saying “two and a bud.”

Manual harvesting (by hand) is the preferred method for many cultivators; however, others prefer the large scale production that comes with mechanized harvesting. It’s an issue of quantity versus quality. The scale made possible by mechanical harvesting is often used for teas with which there is much room for error, imperfection, or damaging of tea leaves and absolute quality isn’t a consideration. These include black teas which undergo the CTC (crush, tear, curl) processing as well as powdered teas like matcha. In mechanized harvesting, workers wear a portable vacuum-like harvesting machine that both cuts the leaf off the bush and collects it in a storage container: imagine a combine used for harvesting corn, but smaller. (check out the video bellow to see the harvesting machine in action)

Withering - Reduction of water content

The goal of all tea undergoing withering is to reduce water content by 50-70%, allow for amino acid degradation, and the development of antioxidants. The leaves can be withered in a variety of ways, such as outdoors in sunlight or in dark, hot rooms. Teas withered in the sun dehydrate faster than those dried indoors because chlorophyll still active in the leaves metabolizes and exhausts the water supply.

The range of withering times for different teas is rather large due to the initial water content of the leaves and the desired flavor development. For example, the chlorophyll content falls as withering time increases. Chlorophyll is associated with the vegetal, earthy flavor in many teas and is the source of “green” in green tea.

Withering times for different teas:

White: 12-36 hours

Yellow: 2-4 hours

Chinese Green: 2-4 hours

Japanese Green: 30-60 min*

Oolong: 30 min - 2 hours

Black: 4-18 hours

*Japanese green teas usually skip the withering stage in order to preserve chlorophyll content but will undergo multiple drying treatments after the enzyme kill stage to reduce water content. If withered, Japanese green teas will only be withered for about 30-60 min.

Enzyme Kill - Reduction of enzyme activity

The goal of the enzyme kill stage is to halt oxidative enzyme activity from the previous stages of tea processing. This is performed by exposing the leaves to high levels of heat for a very short amount of time (60 seconds or less), similar to blanching vegetables. This step is especially important in preserving the desired aromatic and antioxidant compounds of tea. There are four popular methods of enzyme kill: baking, steaming, pan-frying, and GABA.

GABA: Enzyme fixation by nitrogen

GABA: Enzyme fixation by nitrogen

In 1987, Japanese researchers developed a new technique for the enzyme kill stage where, instead of the traditional heat treatment, the tea was given a nitrogen treatment. In doing so, they increased gamma-Aminobutyric acid (GABA); therefore, some teas have gained the acronymed prefix “GABA” (i.e. GABA oolong, GABA green, etc.). GABA is naturally found in the brain and functions as neurotransmitter, stimulating mental activity as well as regulating muscle tone. GABA also creates an interesting purple hue on oolong leaves.

The enzyme kill stage is also referred to as “firing”, “fixation”, and “kill green” (杀青 [mandarin] sha-qing). I refer to this step as “enzyme kill” as I find it to be more all-encompassing and in-line with terminology used in American scientific laboratories.

Leaf Maceration - Physical breakage of leaves

The following four stages are different methods of leaf maceration. They differ in their intensity of maceration, but all of them similarly induce the release of oxidative enzymes by physical means. This results in biochemical changes within the leaves and the creation of new flavors.

Leaf Bruising (oolong and sometimes black teas) - Leaf maceration

The goal of leaf bruising is to create tears in the leaf epidermis, re-instigating oxidation enzymes. Leaf bruising is done by shaking the leaves in a bamboo basket or by machinery, which kneads and tears the leaves (just a little). The bruising can be likened to bruising a fruit, causing the leaves to brown.

Rolling-Shaping - A gentle form of leaf maceration

Rolling-Shaping - A gentle form of leaf maceration

Sweating and Heaping - A rise in thermal enzymatic activity

In various stages and styles of processing, tea leaves are heaped into piles to increase thermal activity and, subsequently, enzymatic activity. The heat created is a byproduct of the metabolic and enzymatic activity within the leaves and is highest in the center of the heap. Tea processors carefully observe temperatures and turn the leaves so they sweat equally throughout.

Oxidation - A chemical reaction involving oxygen

In tea and food, this reaction results not only in a physical browning of the substance (like a banana peel) but also in the creation and unlocking of new compounds at a molecular level. Click the photo to the left for a more information.

Passive Oxidation

This is a natural oxidation lacking an outside stimulus, such as the greening of copper or the rusting of metal. This process is excruciatingly slow in comparison to active oxidation. In regards to tea, the moment the leaf is plucked, the oxidase (oxidative enzymes) are activated, resulting in passive oxidation. During this passive oxidation/withering stage, aromatic compounds especially are likely to develop. This method of oxidation continues throughout withering until it is halted by the enzyme kill stage, where the tea leaves are briefly flashed with heat.

Controlled Oxidation

Controlled oxidation is where the conditions for oxidation have been manipulated by raising room temperature, humidity, and physically breaking the leaf epidermis. The degree of oxidation can be measured in various parameters. For example, in black tea, this process is usually controlled to maintain a specific ratio of theaflavins to thearubigins (usually around 1:10 to 1:12*).

*Spiller, Gene A. Caffeine. Boca Raton, FL: CRC P, 1998. 47.

Drying - Reduction of water content to 3-6%

The goal of the last step is to reduce the water content of the tea leaves down to 3-6%. This will cease all enzymatic activity and preserve the chemical and flavor compounds for the tea’s shelf life. Drying occurs in oven-like rooms where the leaves are laid out in thin layers and dried at 212-248°F (100-120°C). The exact time of drying varies depending on the water content of the leaves prior to drying. For example, Taiwanese-styled oolong tea requires only 5-10 minutes of drying while Indian black teas require up to 20-30 minutes.

Aged Tea -Post-Fermentation and Post-Oxidation

These two techniques are used for the creation of pu’erh and sometimes oolong teas, and involve exposing tea for months to years. Traditionally, these teas would ferment as they picked up microorganisms from exposure on the Silk Road. In modern times, however the tea is stored in dark, humid rooms, conditions which are conducive to microbiological activity and oxidation. Researchers and tea growers continually experiment with new bacterial inoculations to create new pu-erh flavors. Some popular organisms include Aspergillus, Blastobotrys, and Streptomyces*.

*Hou, C.W., K.C. Jeng, and Y.S. Chen. "Enhancement of Fermentation Process in Pu-Erh Tea by Tea-Leaf Extract." Journal of Food Science 75.1 (2010): H44-48. Print.

A final Thoughts on the matter

The possibilities for tea processing are infinite and changing all the time. Tea has been around for thousands of years and the methods of altering its makeup and use are constantly evolving. Don’t be afraid to try new teas, I highly recommend blending different teas together or adding some spices to create a chai!

Some more foot notes to think about:

Avoiding microbiological activity

The utmost care is taken by tea processors to avoid any microbiological activity, which is a polite way of saying rotting or contamination. Tea is not the most encouraging environment for bacterial growth, however, as tea leaves and the liquor they produce are mostly acidic in nature and the finished product contains only 3-6% water, which is significantly below a level supportive of bacterial growth.

Tea growers and processors do, however, take extra precautions to avoid the loss of a harvest. In harvesting stages, tea pickers only select healthy and clean leaves. If any leaves happen to show signs of fungal growth, they are removed from the tree immediately.

Throughout every step of processing, tea leaves are arranged in thin layers and continually turned to allow for adequate exposure to air and inspection. This is why the technique of heaping is more difficult than it may initially sound: if the leaves are not periodically turned, bacteria could potentially grow. The enzyme kill and drying stages are also essential to prevent any bacterial growth.

Hybridization and stage treatments

As mentioned previously, there are multiple steps to each stage of processing. In the case of Japanese green tea, where withering is skipped, the tea will be dried 3-4 times throughout processing. In other cases, some teas undergo a drying treatment in which their leaves are baked, allowed to rest, and then baked rested again for several treatments.

Jeff

May 08, 2013

Long read but I liked how you tried to give different POV with each tea processing subject.

Cheyenne Sweeley

June 18, 2016

This was very helpful! I am hoping thins coming year to start growing and making my own tea and I have been very worried about the process and how everything is done. I am still slightly worried that I will mess up something but I am planning on going to a local tea shop and asking them questions and doing some more research online.

Nigel Melican

July 26, 2016

Nice presentation marred by many errors in process understanding perhaps the most glaring being that black and oolong tea has enzyme kill after withering.

hakizimana Emmanuel

November 07, 2016

there should be clear difference of tea harvesting processes from one region to an other as they are totally different.

Judith

January 27, 2017

This is a great guide for me as I want to go into tea production.